Understanding the Functionality of an Optical Fibre Diameter Analyser in Modern Production

The optical Fibre Diameter analyser serves as a critical tool in modern-day production, supplying specific, non-contact measurements that are important for preserving rigid market requirements. By leveraging innovative laser modern technology, these analysers not just make certain marginal signal loss yet additionally boost the total efficiency of optical fibers.

Value of Optical Fibre Measurement

In contemporary manufacturing, the measurement of optical Fibre Diameter is critical for ensuring the efficiency and integrity of Fibre optic systems. Precise Diameter measurement straight influences optical efficiency, as variations can result in increased signal loss, reduced bandwidth, and lessened total effectiveness. The optical residential or commercial properties, including light transmission and signal honesty, are very sensitive to the Fibre's Diameter, requiring accurate control during production.

Furthermore, standardization in Fibre Diameter is vital for compatibility and interoperability within varied telecommunications networks. As these networks increase internationally, preserving harmony in Fibre characteristics advertises seamless assimilation across numerous components and systems. In addition, adhering to sector requirements worrying Diameter resistances is important for manufacturers to satisfy regulatory demands and customer expectations.

Purchasing advanced dimension technologies not just boosts producing performance but likewise sustains quality control processes, making it possible for producers to determine defects early in manufacturing. This proactive method lowers waste and guarantees that the end products meet strict efficiency standards. Consequently, the value of optical Fibre measurement can not be overstated, as it serves as a structure for top quality, trustworthy Fibre optic systems, which are integral to modern communication facilities.

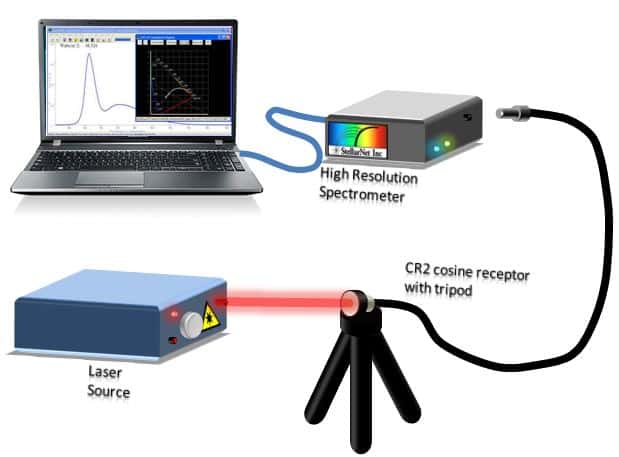

Exactly How Diameter Analysers Job

The core operation depends on the concept of light scattering and representation. As the laser light beam strikes the Fibre, variations in Diameter cause adjustments in the light's intensity and wavelength (optical fibre diameter analyser). This information is processed in real-time using innovative algorithms that translate the optical signals right into exact Diameter dimensions

Additionally, lots of Diameter analysers are geared up with several dimension points along the Fibre, allowing for a detailed evaluation of Diameter uniformity. The implementation of such innovation considerably enhances quality control in production, guaranteeing that optical fibres are produced to exact specs for optimal efficiency in their desired applications.

Key Functions to Take Into Consideration

When selecting an optical Fibre Diameter analyser, a number of vital features require cautious factor to consider to make certain optimal performance and reliability. First, dimension precision is vital; the analyser needs to provide accurate Diameter readings, usually in micrometers, to fulfill rigorous production requirements. Additionally, a wide dimension array boosts convenience, suiting numerous Fibre types and thicknesses.

One more vital function is the analyser's speed. Rapid dimension capacities enable for boosted throughput, vital in high-volume production environments. Real-time information handling and feedback capabilities make it possible for instant changes, boosting high quality control.

User user interface and software program compatibility are likewise significant considerations. An user-friendly user interface streamlines operation, while robust software application assistance assists in information analysis and assimilation with existing manufacturing systems. The ability to export information in different formats can boost reporting and conformity efforts.

In addition, toughness and maintenance needs ought to be reviewed. An analyser created from premium products will hold up against the rigours of a manufacturing setting, while ease of upkeep guarantees long life and reduces downtime. Take into consideration the level of technical assistance and training given by the producer, as this can substantially impact the effective use of the analyser in manufacturing setups.

Benefits in Manufacturing Effectiveness

Enhancing production efficiency depends upon the combination of innovative modern technologies, such as optical Fibre Diameter analysers. These instruments play an essential duty in ensuring that optical fibres satisfy rigid top quality criteria, which is important for ideal performance in different applications - optical fibre diameter analyser. By supplying real-time dimensions of Fibre Diameter, suppliers can promptly recognize and rectify deviations from specified tolerances, therefore reducing waste and minimizing the risk of defective products

Moreover, the early discovery of prospective concerns causes reduced downtime and upkeep costs, therefore enhancing source allowance. Ultimately, the effectiveness gains recognized through the usage of optical Fibre Diameter analysers add to a more affordable manufacturing atmosphere, ensuring that business can supply top notch products while preserving cost-effectiveness and responsiveness to market needs.

Applications Across Industries

The adaptability of optical Fibre Diameter analysers prolongs past manufacturing effectiveness, locating applications across different sectors that rely upon optical Fibre technology. In telecommunications, these analysers are critical for guaranteeing the ideal efficiency of her comment is here Fibre optic cable televisions, straight influencing data transmission prices and network reliability. By precisely gauging Fibre diameters, operators can lessen signal loss and boost total communication high quality.

The clinical sector also benefits substantially from these tools, particularly in the development of endoscopic tools and laser treatments. Exact Diameter dimensions are essential for creating efficient optical fibres that are utilized in minimally intrusive treatments, enhancing individual end results via boosted imaging and therapy capabilities.

In aerospace, the analysers play an important role in the manufacturing of light-weight, high-strength materials, where Fibre optics are incorporated into architectural parts for monitoring and diagnostics. Additionally, the automotive industry uses these tools to make certain the integrity of Fibre optic sensing units that improve security and performance features visit this page in vehicles.

Conclusion

In conclusion, the optical Fibre Diameter analyser is essential for modern-day manufacturing, ensuring specific measurements that promote sector requirements. The varied applications across numerous markets emphasize the analyser's importance in advertising constant improvement and data-driven decision-making within the manufacturing field.

In contemporary production, the measurement of optical Fibre Diameter is crucial for ensuring the efficiency and reliability of Fibre optic systems. The value of optical Fibre dimension can not be overemphasized, as it serves as a structure for top have a peek at this website quality, trustworthy Fibre optic systems, which are integral to modern-day communication facilities.

Diameter analysers employ sophisticated optical modern technologies to accurately determine the Diameter of optical fibers.Additionally, lots of Diameter analysers are equipped with multiple measurement factors along the Fibre, permitting for an extensive evaluation of Diameter uniformity.The versatility of optical Fibre Diameter analysers prolongs past making performance, finding applications across different markets that count on optical Fibre modern technology.

Comments on “Top Benefits of Using an Optical Fibre Diameter Analyser in Optical Fibre Production”